-

Document Control

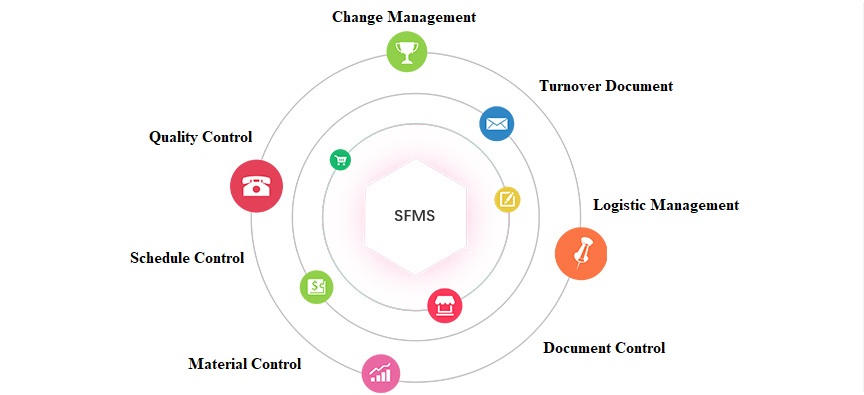

SFMS can perform project documents control: support the digitization of paper documents, which can be collected and managed centrally; standardize the document classification, directory structure, hierarchical division, custom labels, and classification; support multiple ways to retrieve drawings, procedures and materials certificate and test report online in real time; support version control management, which can compare differences between different versions. According to the actual requirements of the project, SFMS can be customized download, distribution, approval authority, etc., And also has achieved digitalization, linkage and standardization of document control.

-

Safety Management

SFMS can perform safety management: through the form of Accident Predictive Technique (APT), all employees of the company can participate in safety, and then analyze the APT data is analyzed to formulate effective prevention and resolution measures; in the process of project execution, by associating the work package in SFMS with Job Safety Analysis (JSA), the identification of environmental factors and hazards in operation, and risk assessment and control were realized. At the same time, the operation and execution of the construction site was standardized, the occurrence of accidents was minimized. Yanda can achieve the goal of safety management: "zero accidents, zero injuries, zero pollution, and zero complaints."

-

Quality Control

SFMS can perform quality management: establish digital ITP to control the key points of quality inspection; realize real-time data monitoring and analysis of the fabrication process; help the project achieve warning of quality risk and actively take effective measures to improve product quality. Among them, the welding pass rate (RT) ≥ 99.4%; support paperless management of inspection reports and online real-time review and audit; remote inspection equipment is perfectly associated with SFMS, and database information can be retrieved in real time on site to better support and promote remote inspection.

-

Material Management

SFMS can perfom material management: support procurement plan management, material in-out management, material supply and free issue material management, inventory management, material matching and traceability management, authority management and other management functions. Among them, material matching management can realize the many functions such as project material pre-matching, maximizing matching, locking matching and designated matching, etc., which maximizes the flexibility of material use. In addition, SFMS is the first to use codes and RFID in material traceability management, and the whole process records the life cycle of materials in the construction process of the project, effectively reducing the circulation link, preventing backlog and waste, shortening schedule, accelerating construction and increasing project profit.

-

Schedule Management

SFMS can perform schedule management: all aspects of the project has been connected through SFMS from engineering, procurement, production to delivery, maintenance, and by completely integrating AWP concept and requirements, scientifically executing the construction plan, accurately determining the execution target, fully preparing the project schedule and resource supply plan. It has realized smart production such as automatic production scheduling, information reporting and releasing, production process monitoring, quality online monitoring, unified material distribution. It can display the comparison of construction plan and actual performance in time through the mobile phone or computer, promptly remind the project delay, and fully provide various analysis progress reports. At the same time, it supports the visual management and control via the device, and remotely monitors the actual progress of the project site in real time through the Internet or mobile terminal.

-

Change Management

SFMS can perform change management: the product will set up production processes and standardized operating procedures in the early stage of the project. SFMS can track the full life cycle of the product and make judgments and production instructions on changes that occur during the project execution process, which can improve the efficiency of change processing and reduce the impact and waste of change. Also, SFMS makes changes reasonable, controllable, traceable, and makes change process more standardized.

-

Turnover Documents

SFMS can perform turnover documents management: the SFMS platform has broken through the data chain of engineering, construction, material supply and production operation management, and collected effective data and reports timely, accurately and in real time during the project execution process, which can realize one-click export the electronic turnover documents in the final documents submission stage and also support progressive documents submission during the project.

-

After-sales Management

SFMS can perform after-sales management: it has established a management service platform for on-site installation, including document management, material management, schedule management, change management, turnover documents management, etc., which can effectively ensure the site construction execute efficiently and promptly. In addition, the SFMS database can provide related solutions and service support for site product maintenance, repair, procurement, etc. on projects that have been put into operation. At the same time, it is making full use of the analysis advantages of SFMS big data, we continue to optimize and improve after-sales service to give our clients a better experience.